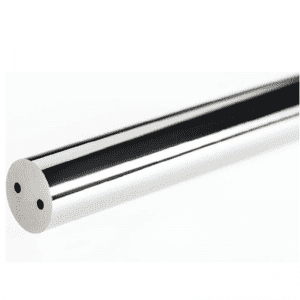

Wolfram-Vollhartmetall-Stäbe für Schaftfräser und Bohrer mit stabiler hoher Qualität

1.Die Hartmetallstäbe aus Wolfram werden durch Formen oder Extrudieren pressgeformt.

2. Die Hartmetallstäbe aus Wolfram werden durch einen integrierten Niederdruck-Sinterofen gesintert, wodurch die Gesamtleistung hoch ist.

3.Der raue Wolfram-Kobalt-Karbid-Rundstab oder der Außendurchmesser des Rundstabs können entsprechend jeder Toleranz verfeinert und poliert werden. Die gängigen Toleranzen sind h5, h6, -0,005 usw. und auch die Endfase der Hartmetallstangen kann bearbeitet werden.

Stäbe 4.Carbide eignen sich für die Verarbeitung von allgemeinem Stahl, Gusseisen, Edelstahl, hitzebeständigem Stahl, Nickelbasis und Titanlegierung. Empfohlen für Allzweck-Hartmetall-Werkzeugmaterialien wie Spiralbohrer, Schaftfräser, Gewindebohrer und Tieflochbohrer.

Unsere Arten von Hartmetallstäben

1.Ungeschliffene lange Stangen

| Die TOL. von ungeschliffenen langen Stäben | ||

| Größe (DxL, mm) | Toleranz | |

| D(mm) | L(mm) | |

| D[1-3)x310/330 | 0,30~0,55 | 0,00~+4,00 |

| D[3-12)x310/330 | 0,30~0,60 | 0,00~+4,00 |

| D[12-20)x310/330 | 0,30~0,65 | 0,00~+4,00 |

| D[20-40]x310/330 | 0,30~0,70 | 0,00~+4,00 |

2.Ungeschliffene abgelängte Stangen

| Die TOL. von ungeschliffenen abgelängten Stäben | ||

| D/L (mm) | Die TOL.of D&L in mm | |

| L<=70 | 70<L<=150 | |

| D<5 | D(0.20~0.30), L(0.20~1.5) | D(0.25~0.35), L(0.20~1.5) |

| 5<=D<40 | D(0.25~0.35), L(0.20~1.5) | D(0.30~0.40), L(0.20~1.5) |

3.Ground long rods

The tolerance of the long rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+5.00mm in Length as normal.

4.Ground cut-to-length rods

The tolerance of the ground cut-to-length rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+2.00mm in Length as normal.

5.PCB Rods

more than 50 years production and management experience,Advanced production technology, High-precision machines, Strict QC management system, Special-designed packing boxes and tubes, Various shipping methods

1.Tungsten carbide blanks production

Good quality carbide products rely on 100% virgin raw materials and advanced wet-milling,pressing machines and sintering furnaces. We put emphasize on every production process of our carbide blanks. To keep good quality of carbide blanks is the base of furtherly machined high precision finished carbide parts.

2.Inspection and testing process

In order to ensure the quality of all our tungsten carbide finished products, a very strict QC management system we called “Quality Control Center” has been introduced. With our advanced inspection equipment and our professional inspectors, we are able to do raw materials inspection, on-site inspection and after finishing inspection to ensure 100% good quality of your carbide products.

3.Advanced CNC Equipment

NCC owns a series of high-precision grind machines, including flat grinding machines, OD and ID machines, Centerless grinding machines and customized grinders. Also we have CNC machines, EDM, Wire-cutting machines and drilling machines etc. With our skilled workers, we can control very high precision of each carbide part.

4.Packaging and Shipping

Special-designed packing boxes and tubes will be used properly for the standard and customized carbide products to ensure the safety of the goods during the transportation process.A wide range of shipping ways can be available for your shipments, for example we can ship goods by Sea, by air and by Express companies like DHL/FedEx/UPS/TNT etc.